AMS AIRLINES & MRO Features

AMS® is the powerfull solution and dedicated to manage all your :

Aircraft, Engine & Component

Airworthiness Management

Maintenance Management

Logistic & Purchase Management

Transportation

Stock analysis

Human resources

Documentations & Manuals follow-up

Cost analysis and forecast

Reliability, Quality Assurance

Accounting data management

Certification qualification

Certification Qualification Management

Employee Records

Inventory Management

Statistic reports / Excel template export

Claims Management

Production Plan

SOFTWARE PHILOSOPHY

ICAO, FAA and EASA require that all airlines must have a complete control of their Aircraft, Engine & Component airworthiness management in order to enhance the flight safety.

With AMS, all mandatory or optional maintenance requirements must have an application limit. Deadlines can be deferred or not in accordance with the airworthiness impact level or in accordance with the maintenance program and the minimum equipment list.

AMS allows you to follow-up and launch all maintenance requirements from a single display and to build work package using drag and drop for an aircraft, engine or component.

The hard competition between airlines commits them to plan the aircraft maintenance checks, to reduce the aircraft downtime and associated costs. AMS will give you the tools to link all maintenance requirements with the logistic and purchase modules in order to facilitate the short and long term decisions.

Airlines and MRO’s need to manage their fleet maintenance planing by realtime forecasting based on their own aircraft monthly utilization rate including associated costs.

AMS will allow you to plan and provide a daily, monthly or yearly realtime forecasting for all the mandatory or optional works you have to perform on your fleet with their provisioning status and costs.

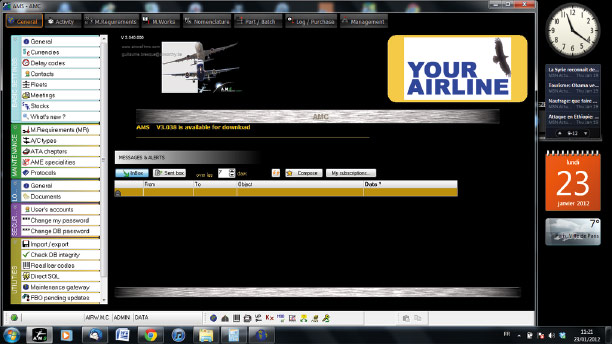

AMS ON-LINE SOFTWARE

AMS® MAINTENANCE PACK is the solution for managing your maintenance. Entirely designed by aviation professionals, AMS® is dedicated to airlines and maintenance repair organizations. AMS® is a full support tool for aircraft, engine and component airworthiness control and for producing official reports (AD, SB, hard time, life limit part, modification and structural repairing status, etc.) and issue your maintenance program and associated amendment.

Activity module allows you to manage your Flight Log Book sequences, Legs, FH & FC (atypical), Crew, Hydraulic, Fuel…Daily Line maintenance, Technical Log Book, Cabin Log Book, PIREPS, MAREPS, HIL, MEL limitations, A/C technical situation with relevant logistics details… statistics, delays…

Airworthiness / maintenance requirements module gives you the tools to manage your maintenance program and associated revision, AD, SB, ALI, CMR, AWL, CPCP, EWIS, CDCCL, components, modifications, structural repairs, LLP status, engineering orders…

Maintenance schedule module provides your aircraft, engine and component maintenance planning, forecast, work orders, work packages including related men hours with part request process in real-time, tools, opening access, release certificates.

AMS® can generate & send automated part quotations to all your suppliers and also gives you the tools and allows you to manage with different module your complete supplier chain :

Part number (Nomenclature) Module allows yout to manage your part reference maintenance & reliability, Price & providers, Effectivities & alternates, Stock positions & alert quantity, automatic provisioning, Resources including alternates, History and cost.

Stocks including Assembly/Sub-assembly Module will manage your multi-stock and parts values and acquisition cost, inventory, history, shelf life, Part limitations, Works history, stock inventory and value graph, scan and attached documents, tags, etc…

Full Logistics & purchase processes and traceability module AMS® easily manages all your supplier chain : Provisioning requests,Request for quotation (automatic sent & reply), Release certificates…

Full Logistics & purchase processes and traceability module AMS® easily manages all your supplier chain :

– Provisioning requests,

– Request for quotation (automatic sent & reply),

– Purchase orders,

– Standard exchange plus cost, Standard exchange flat,

– Loan and Rentals,

– Repair evaluation orders & Repair orders,

– Requisitions for Power by hour contract,

– Invoices and associated payment,

– Deliveries documents,

– Material receipt process, Quarantine

– Removal/installation tags,

– Part assignation,

– Part scrap process,

– Customer quote,

– Release certificates,

– Airway bill & forwarding agent

– Packing slip & proforma invoice,

– Claims & Warranties…

– Bar code identification follow-up for all parts and logistic and purchase electronic documents.

– Accounting entry table (general & analytic)

– KPIs

From a single aircraft to hundreds. From a standalone use to client /server with unlimited number of users

An intuitive user interface (Windows based) with immediate links across all modules. All is made for minimizing your time and enhance the user’s productivity.

Intensive use of the mouse and mouse wheel, selection boxes, drag and drop, etc. Maintenance checks real time follow-up thru the use of bar codes.

Transactional database, automatic database saving (each day, on a 7 days cycle – plus hardware data mirroring), systematic confirmation and checking of user’s actions: no data are recorded until the user confirms (or cancels) his action, the server logs the user actions (User name / date and action are recorded).

AMS® is entirely designed in accordance with the main aviation rules applying to maintenance and airworthiness management procedures (e.g. EASA part M, PART 145, PART 66).

to maintenance and airworthiness management procedures (e.g. EASA part M, PART 145, PART 66).

The AMS® user manual can be called directly from your own procedures.

SUBPART C – CONTINUING AIRWORTHINESS

✓ M.A.301 Continuing airworthiness tasks

✓ M.A.302 Aircraft Maintenance Programme

✓ M.A.303 Airworthiness directives

✓ M.A.304 Data for modifications and repairs

✓ M.A.305 Aircraft continuing airworthiness record system

✓ M.A.306 Operator’s technical log system

✓ M.A.307 Transfer of aircraft continuing airworthiness records

SUBPART D – MAINTENANCE STANDARDS

✓ M.A.401 Maintenance data

✓ M.A.402 Performance of maintenance

✓ M.A.403 Aircraft defects

✓ M.A.504 Control of unserviceable components

SUBPART F – MAINTENANCE ORGANISATION

✓ M.A.606 Personnel requirements

✓ M.A.607 Certifying staff

✓ M.A.608 Components, equipment and tools

✓ M.A.609 Maintenance data

✓ M.A.610 Maintenance workorders

✓ M.A.611 Maintenance standards

✓ M.A.612 Aircraft certificate of release to service

✓ M.A.613 Component certificate of release to service

✓ M.A.614 Maintenance records

SUBPART G – CONTINUING AIRWORTHINESS MANAGEMENT ORGANISATION

✓ M.A.704 Continuing airworthiness management exposition

✓ M.A.706 Personnel requirements

✓ M.A.707 Airworthiness review staff

✓ M.A.708 Continuing airworthiness management

✓ M.A.709 Documentation

✓ M.A.710 Airworthiness review

✓ M.A.712 Quality system

✓ M.A.714 Record-keeping

SUBPART H – CERTIFICATE OF RELEASE TO SERVICE – CRS

✓ M.A.801 Aircraft certificate of release to service

✓ M.A.802 Component certificate of release to service

SUBPART I – AIRWORTHINESS REVIEW CERTIFICATE

✓ M.A.901 Aircraft airworthiness review

AMS® is a 100% native source code: No link to third-party software, integrated database engine, integrated report builder. For the end user, this is the best warranty for a high integrity level and for overall efficiency.

database engine, integrated report builder. For the end user, this is the best warranty for a high integrity level and for overall efficiency.

The AMS® cost of ownership combined with its maintenance costs benefit result in a highly cost effective solution.

Each technical department works in synergy with the others using the AMS® main modules:

– Aircraft Activity

– Maintenance Requirements,

– Maintenance Schedule, Work Package

– P/N (Nomenclature)

– Components / Batches

– Logistics & Purchase

– Management

Record and/or share any associated document (any electronic format) or scan directly the document using the embedded scanner driver.

Single point administration, no need of expensive support services for deploying new releases:

Automatic upgrade of the clients over the network,

Automatic database upgrade

AMS® provides new releases every two months

Contrary to the other airworthiness management software, AMS® has a single module to generate reliability data so there is no need to compile the information from various modules to generate a proper reliability report. AMS® does it all automatically. Following are reliability data immediately available: Technical dispatch, consumption (Fuel, Oil, Hydraulic), Monthly reliability report, Components (MTBR, MTBUR…)…